Older Vehicles Are Not Necessarily Easier To Fix

The majority of calls we receive on our technical help line are with vehicles 15 years old and newer. With the complexity of newer vehicles, these calls have become increasingly more difficult to do. Suffice it to say that when a call comes in for a vehicle that is from the ’90s or the early 2000s, it usually becomes a break against the brain burners we normally receive. That doesn’t mean the older vehicles are immune to being difficult. There are plenty of times when those seemingly “easier” calls come in and end up being a “lunch eater.” These problems may arise due to maintenance not being in the owner’s vocabulary. Or, when previous work was performed with incorrect parts, or a non-sophisticated operational system is not completely understood. Such was the case with a 2001 Isuzu NPR 4.8 Diesel using the Aisin 450-43LE Transmission. After many failed attempts at fixing a TPS code 21 from a variety of shops, it eventually found its way to Lorenzo Ortiz at Phillips Transmissions in Arizona.

Lorenzo questioned the owner of the truck where he learned that both the TPS and the TCM had already been replaced by one of the shops in their attempt to resolve the problem. His initial diagnosis verified that TPS code 21 was stored (Figure 1), yet the TPS was functioning correctly at the TCM. Power and grounds at the TCM were checked and determined good. After clearing the code and test driving the vehicle, it is noticed that the PID for the engine RPM read nothing and the idle switch read “engine is NOT at idle” when in fact it was (Figure 2). By punching the throttle to see if a change would occur, an 800-plus RPM suddenly appeared near wide open throttle at which time code 21 for the TPS set.

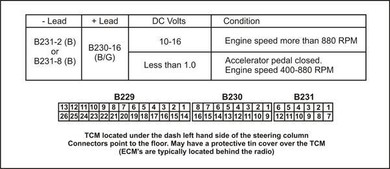

| Lorenzo referred to a wiring diagram in preparation for inspecting the engine RPM sensor and idle switch. It was then discovered that this vehicle does not have an “actual idle switch” and the tachometer sensor is the signal source for engine RPM. It is the ECM that determines an idle signal, which is presented in the scan tool and an idle switch.The way this works is that there is a 12-volt wire fed from the TCM to the ECM. The ECM determines idle speed from the tachometer sensor and will ground this wire when it determines that the engine is at idle speed. Idle speed is 790-870 RPM. When engine speed increases above 870 rpm, the ECM will release the ground on the signal wire from the TCM.

|

The reason for setting the TPS code is that without an RPM signal due to the defective tachometer sensor, the ECM will not ground the signal wire to inform the TCM of an actual idle condition. When the engine was revved up, an RPM signal finally registered at 800 RPM, at which time the ECM grounded the signal wire to indicate an idle condition. Meanwhile, the TPS voltage is showing that the driver is deep into the throttle. With the TPS voltage being a different value than what the idle signal indicates, code 21 for the TPS is set.

Example: TPS value at idle should be 4.0 to 4.9 DC volts and engine RPM should be between 790-870 RPM. The Idle signal in the scan tool will be “yes.”

In this scenario, there was no engine RPM at idle and the idle switch in the scan tool said “no.” TPS voltage was between 4.0 and 4.9. When the throttle was depressed, a false 800 RPM signal was generated by the tachometer sensor while TPS voltage dropped appropriately to 3.0 volts. When the ECM saw 800 RPM, it grounded the TCM signal wire to indicate and idle condition.

Not knowing the way this unique system operates will certainly cause some head scratching. But what brings this head scratching to the point of balding is that there are no codes assigned to the tachometer or for an idle switch signal fault. This means that when these signals malfunction, the TPS will always be blamed as the offending component. Additionally, the defective tachometer sensor did not produce any other drivability complaint as one might think.

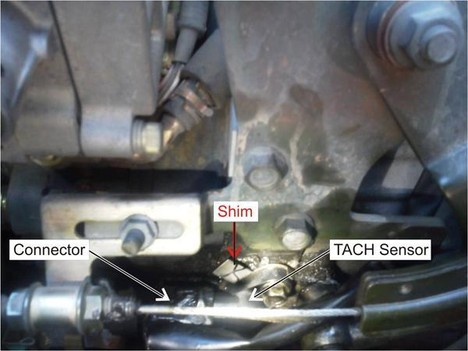

The part number for this sensor is 8-97214325-0. Use caution when replacing the sensor. There is an air gap spacer shim located under the sensor that could fall away unnoticed. This shim needs to be installed with the new sensor for it to function correctly (Figure 5). Once the shim and tachometer was replaced, engine RPM in the scan tool displayed 800 RPMs and the idle signal said “yes.” When engine RPMs were brought up past 870, idle signal said “no.”. Problem solved.

Part Number 8-97214325-0

Rolando Farradas from Rainbow Trans & Auto Center knows well of another cause for TPS code 21 to set that will drive you beyond balding. It has to do with using incorrect parts. In this case, an engine exchange or rebuilt with the wrong parts or, an incorrect computer was used.

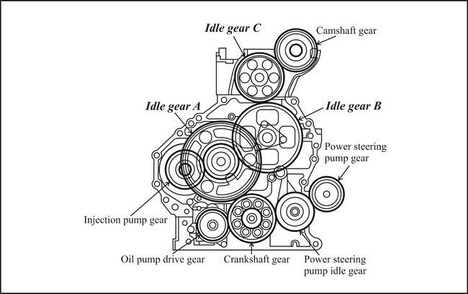

1999 NPR vehicles using a diesel engine with the 450-43LE transmission only use fine pitched idler gears. The crank shaft drives idler gear A’s larger gear. The inner gear on idler gear A, which is fine pitch, drives the injector pump and idler gear B. Idler gear B then drives idler gear C, which drives the cam shaft seen below.

Cam Shaft

Cam Shaft

2000 and later vehicles use course-pitched idler gears. If these engines are swapped or the wrong idler gears are used when rebuilding the engine, the engine RPM sensor will provide an incorrect signal to the ECM, causing TPS code 21 to set.

1999 TCMs have an orange connector programmed to properly read fine-pitched gears, while 2000 and later have a green connector programmed to properly read course-pitched gears. There are two different size TCMs with green connectors, which will interchange with any 2000 to 2006 vehicle using the 450-43LE transmission. All ECMs have a green color connector, and they vary, matching the type of engine used (4HE1TC, 4HE1-XN, 4HF1, 4HG1T, 4HK1-TCN, 4HK1-TCC, 4HK1-TCS, 4HJ1, 4HJ1 etc.).

Orange and Green Connector

If an error has been made by rebuilding the engine with the wrong idler gears or from swapping out the engines incorrectly, there is some good news. For example, if a 2000 engine has been installed in a 1999 vehicle, which is now producing code 21, the matching ECM and TCM can be installed to correct this condition. The harness connector configurations are all the same, allowing for these computers to be interchanged. Another entirely different scenario that is near always misdiagnosed has to do with Ford trucks using the 7.3L Powerstoke engine.

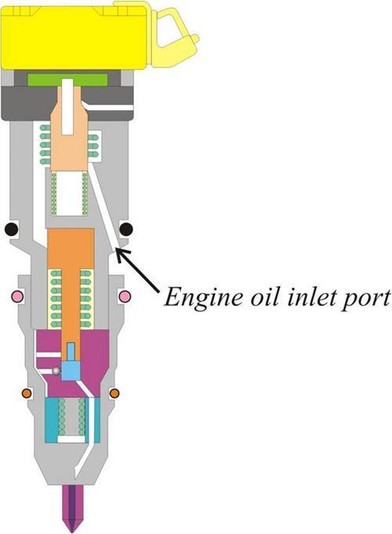

The scenario goes like this: A 2001 F-350 Super Duty 7.3L vehicle with a 4R100 transmission comes in to your shop with a customer complaint of what is perceived to be a bind-up or a holding-back sensation. This problem occurs when the vehicle is carrying a load backing up a hill or on flat ground with aggressive rearward acceleration. The transmission fluid level and condition does not reveal a transmission problem. The transmission may have been disassembled for inspection, but nothing is discovered that would cause such a complaint. No diagnostic codes are stored in the system either. The transmission can be swapped out with another, yet the bind up feeling in reverse remains. 7.3L Powerstroke engines have a capacity to hold 15 quarts of oil (14.2L). Besides the engine oil being a lubricant, it is also part of the fuel system.

For engine techs, this is “old hat” (covering the balding from years of head scratching). For most transmission techs, this fuel system is called the hydraulically activated, electronically controlled, unit injector fuel system. The system uses a high-pressure volume pump by Bosch to transfer engine oil through the poppet valve to the top side of the intensifier piston inside the fuel injector. The surface area of this piston is seven times greater than that of its plunger. So, if there was 1,000 psi of injection control pressure (ICP) across the intensifier piston, this would convert to 7,000 psi of fuel injector pressure.

If engine oil level is low, the injectors do not work properly, affecting fuel delivery to the combustion chamber. In the case of this complaint, engine oil was down approximately 5 quarts. When the vehicle was backing up a hill with a heavy load, low oil level became lower, compromising the high-pressure pump’s ability to deliver the necessary ICP to the injector, which in turn affected fuel delivery. The lack of fuel pressure caused a bogging-down sensation simulating what was perceived as a binding-up or a holding-back sensation originating from the transmission while in reverse.

The real fix needed here is to inspect and correct any engine oil leaks and bring the level up to specifications using SAE 15W-40 Super Duty Motor Oil XO-15W40-QSD or equivalent. As a side note, the 6.0L Powerstroke engine near doubles the high-pressure system using a more complex injector than that of the 7.3L. Being a more complex injector seems to have made it a more problematic injector. A common complaint when these begin to fail is the vehicle has a difficult time starting when cold.

Low engine oil can affect the transmission and occurs with Chevrolet Cobalt vehicles equipped with the 2.4L engine (Variable Valve Timing) and the 4T45E transaxle. The vehicle comes in to the shop exhibiting very harsh shifts. The check engine light is on and when checked, a P0010 for an Intake Camshaft Position Actuator Solenoid Control Circuit fault is set or a P0011 for an Intake Camshaft Position Actuator Solenoid System performance fault is set.

The cause again can be low engine oil, but it also could be a faulty Intake CMP actuator causing a performance problem with the actuator. Both of these codes will raise line pressure causing the shifts to be harsh. This is not mentioned in the code explanation for P0010 and P0011 under the heading called “Action Taken When the DTC Sets.” This can cause one to think a transmission problem is also at play when it is not.

To correct this condition, clear diagnostic trouble codes and verify that the engine oil level is correct. This is the first step in the diagnostic tree as low engine oil can cause improper control of the Intake CMP Actuator. Drive the vehicle to see if the code resets. If the P0010 resets, refer to the appropriate factory manual to check the electrical circuit of the actuator.

These are a sampling of some of the problems that can catch you off guard as these vehicles get older. Just because it’s old and familiar doesn’t mean diagnosing the problem will be quick and easy.