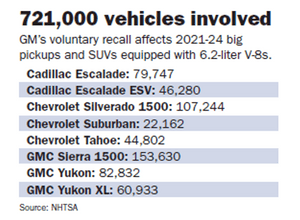

One of General Motors’ most prized powerplants—the 6.2-liter small-block V8—has hit a major bump in the road. A voluntary recall of over 721,000 engines used in Chevrolet and GMC pickups, as well as GM’s full-size SUVs, has become a rare and expensive misfire for a company known for its V8 dominance.

This isn’t just another recall. The affected engine, built in GM’s Tonawanda, New York, facility, is the latest evolution of GM’s iconic workhorse—the Chevrolet small-block V8. Now, engineers are scrambling to identify what’s gone wrong with engines that, in some cases, have seized up with just a few hundred miles on the clock.

What Went Wrong?

According to GM, the root of the issue lies with supplier and quality problems. In an email to Automotive News, GM cited two primary culprits:

-

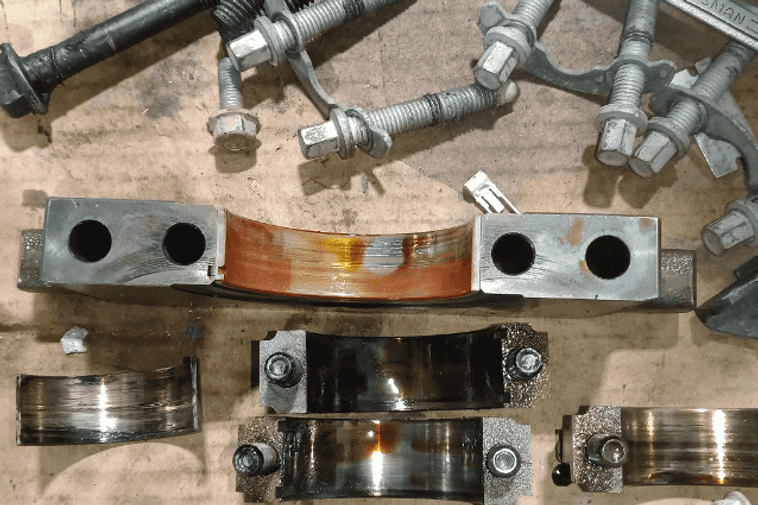

Rod bearing damage caused by sediment in the oil galleries of the connecting rods and crankshaft.

-

Out-of-spec crankshafts with incorrect dimensions and surface finishes.

The faulty parts came from two suppliers: American Axle & Manufacturing, which provided the connecting rods, and Questum Macimex, a Mexico-based supplier responsible for the crankshafts. These defective components found their way into engines built between March 1, 2021, and May 31, 2024.

GM has reportedly been aware of the problem since 2022 and has already conducted multiple investigations. To date, the company has logged over 28,000 complaints, with more than half related to a total loss of propulsion. CFO Paul Jacobson estimated the cost of the recall will hover around $500 million.

Dealer Dilemmas and Delays

Dealers on the front lines are already feeling the heat. At Starling Chevrolet-Buick-GMC in St. Cloud, Florida, Service Manager Jay Golston says they’ve seen at least 15 failed engines. But there’s no clear direction yet on how to prioritize these engine replacements, each of which takes a minimum of 22.4 hours.

Some replacement engines have begun arriving, but the rollout appears inconsistent. Vehicles with dead engines are sitting outside dealerships waiting for parts, with weather exposure and battery drain adding more headaches.

“It creates major heartburn for the dealer,” Golston said. “Once you disassemble that vehicle, it’s pretty much a manual push-in and out.”

What’s Next for Owners?

GM has a detailed plan in the works to inspect—and if needed—replace affected engines. Owners will receive notification letters starting June 9. Vehicles will first be inspected, and even if no issues are found, they’ll receive an oil change to switch from 0W-20 to 0W-40, a new filter and filler cap, and an update to the owner’s manual. The thicker oil offers more protection under high-stress conditions.

If an engine fails inspection, GM will replace the entire unit, not just a short or long block. That means no parts reuse, just a brand-new engine dropped in.

While GM believes only a small fraction of the engines will require full replacement, each inspection is labor-intensive, and powertrain engineers are still refining the testing process to identify internal wear.

Meanwhile, GM’s Tonawanda plant is ramping up production to reduce the backlog and meet the demands of the recall.

A Broader Industry Trend?

GM isn’t alone. In 2023, Toyota recalled 100,000 V6 engines used in the Tundra and Lexus LX, requiring months to prepare dealerships for replacements and develop special equipment for the job.

Of the 721,000 engines included in GM’s recall, nearly 600,000 are in the U.S., with the rest spread globally. With 420 horsepower, the 6.2-liter V8 remains GM’s most powerful offering in pickups and SUVs—and one of its most profitable. For now, it’s still available as an option, but its reputation is undeniably under pressure.