A Look At Ford and GM’s Jointly Built 6T40 Transmission

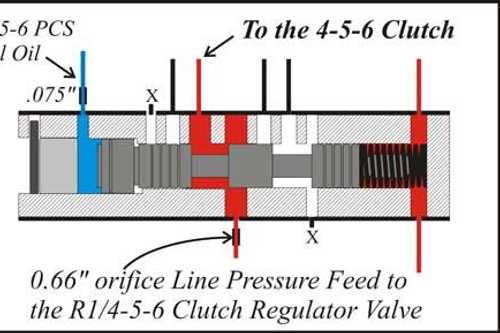

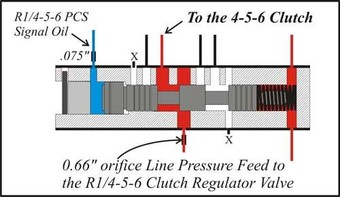

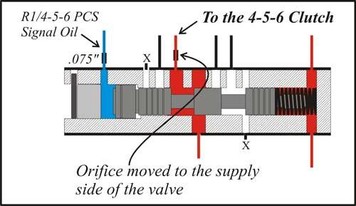

With the exception of the Low and Reverse Clutch, each clutch inside this transmission is operated by a solenoid through its respective regulating valve. With Gen 1-based models, a relatively small feed orifice was located on the line pressure supply side of the 4-5-6 Clutch Regulating Valve. With this orifice on one side of the valve and the wave plate on the opposite side of the valve, it stabilized the valve from having a pressure spike when it moved from a full feed position to regulation. When the cushion (wave) plate was removed to add an additional friction plate for increased torque capacity, this orifice was moved to the clutch pressure supply side of the valve. This was done to have a greater control of the apply of the clutch to prevent a harsh engagement with the absence of a cushion plate.

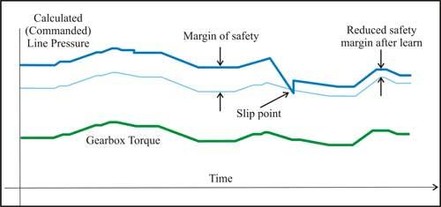

| One software change that took place is related to fuel economy, which affects how the TEHCM controls line pressure inside the transmission. Typically, once a shift transition is made, line pressure is increased and held so as to keep the driving or holding clutch from slipping, maintaining the commanded gear. The engine then drives the pump through the torque converter. When line pressure becomes high, this places an additional mechanical load on the engine, negatively affecting fuel economy. For Gen 2, a “system pressure learn” program was written where the computer will periodically bring line pressure down until it sees it slip. It will then raise line pressure just slightly above the slip point, minimizing the margin of safety between slip and non-slip conditions. By doing this, the engine is driving a pump at lower pressures for longer periods of time. This places less load on the engine and thus increases fuel economy. |

We hope you are finding this particular article series useful. More to come about Ford and GM’s jointly built 6T40 transmission!